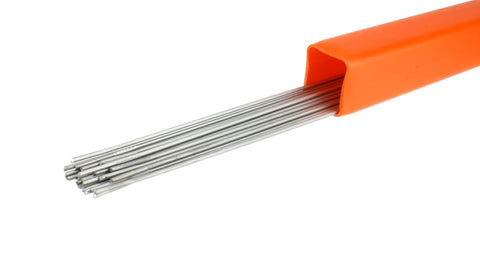

- ***READ THIS: Check Picture #2 for an approximate number of rods per pound. The main image is for reference only. These rods are shipped in a reusable plastic container with a cap that can be used to safely store and transport your rods. Read the description of this product below for a general guide on how to weld titanium.

- This ERTi-2 Titanium TIG Rod was developed for welding Titanium grades 1, 2, 3, and 4. It is the most commonly used titanium alloy in the industrial corrosion market because of its availability and lower cost. A very common application of ERTi-2 is in electrolytic applications such as anode substrates for the production of chlorine and sodium chlorate. Also used in process equipment such as pressure vessels, columns, tanks, heat exchangers, s afts, blowers and fans, condenser tubing, valves, fitting, and pipes.

- These rods comply with AWS a 5.16 : ERTi-2, EN ISO 24034 : STi-0120 (Ti 99, 6) and DIN 1737 : SG Ti 2. - Recommended GTAW Welding Parameters "" DCEN (DC-) "Shielding gas: use 100% Argon or Argon/Helium for greater penetration and higher speeds "Tungsten: use 2% Thoriated, 2% Ceriated, 2% Lanthanum or Rare Earth. Available Diameters: 0.035", 0.045", 1/16", 3/32" and 1/8" - Available Pack Quantities: 10 Rods, 1 Lb and 2 Lb - Select your option from the Size Menu. Instructions for Welding Titanium: Titanium is generally welded using the same techniques like Stainless steel, however, titanium requires much greater weld joint cleanliness along with extensive inert gas shielding.

- "Cleaning: Grind or file away mill s ale. Remove surface oxides with Pickling Paste or 35% nitric "" 5% hydrofluoric acid solution at room temperature. Remove any grease or oil with a nonchlorinated degreasing solvent, methanol acetone, or methyl-ethyl-ketone. Light oil can be removed by washing with a household abrasive or detergent.

- "Fitup: Clamp joints where possible. Tack welds require the same care as other welds. "Equipment: use a cons ant-current power source (DCEN) for GTAW with a contactor for arc s art and stop. High-frequency s arter for manual welding, water-cooled GTA torch with gas lens and -inch (#12) gas cup, 2% Thoriated, 2% Ceriated, 2% Lanthanum or Rare Earth tungsten Note: A reactive metal, titanium is sensitive to embrittlement by oxygen, nitrogen, and hydrogen.

- Consequently, the molten weld metal must be protected against atmospheric contamination by holding the shielding gas over the weld zone until it cools down to 600F

Customer Reviews

Based on 1 review

Write a review